Roof sag, as its name implies, occurs when a roof sags or bends from its original shape. This structural issue often stems from misaligned load paths and undersized structural roof supports.

To better understand roof sag, it’s first important to familiarize yourself with common roofing systems. Today’s residential construction industry utilizes two main systems: rafters and trusses.

Rafters are field cut by carpenters (a process known as “stick framing”), whereas truss systems are pre-engineered. Trusses are built in a controlled shop environment and delivered to the jobsite already assembled.

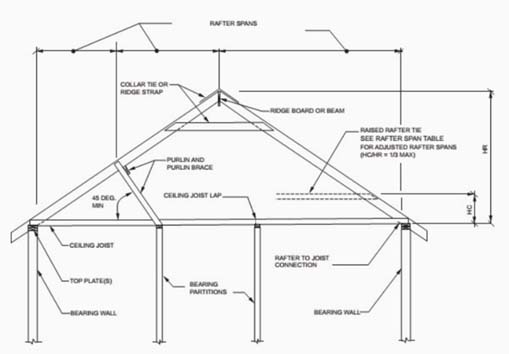

Below is an example of a rafter system:

Your local Authority Having Jurisdiction (“AHJ”) and building codes will provide guidance on the sizing of structural roof members. These must be designed by a licensed professional engineer or architect.

In this guide, we’ll dive into rafter systems first.

Rafter Systems

Rafters are typically sized based on lumber grade, spacing, dead load (“weight”), live load (or “snow load”), and ceiling deflection criteria. The most common rafter size is a 2”x 6”, though these are not typically adequate without proper bracing (known as “purlins”). Since purlins account for most of a roof’s actual weight, it is critical they be supported by a bearing partition wall (See Figure 2).

In some cases, however, builders fail to realize this and instead select a nearby, non-bearing wall for the sake of convenience. This can result in a misaligned load path, which may in turn cause long-term floor and roof sag, since interior floor joists are not sized for roof loads.

Your roof and ceiling assembly need to provide continuous ties across your home structure to prevent roof thrust from being applied to your supporting walls.

There are generally two rafter-framed ceiling styles: flat or cathedral.

With a flat ceiling, the ceiling is not attached to the rafters, it is connected to the ceiling joists; in this system, there is a non-structural “ridge board.” A cathedral-style ceiling is attached directly to the rafters and contains a “ridge beam,” which is a structural member. The deflection design criteria for a cathedral ceiling are much more stringent than those for a flat-style one, due to the attachment of the finished surface below.

Whether you opt for a ridge-board design or a ridge-beam design, there are some key considerations you’ll need to consider to ensure the longevity of your roof.

Ridge Board Considerations:

- The ridge board located along the peak effectively serves as a rafter bearing and nailing surface for the opposing rafters. For this reason, its depth must be enough, as is required by code: “A ridge board used to connect opposing rafters shall be not less than the cut end of the rafter.”

- Opposing rafters must be aligned correctly. They cannot be framed more than 1-1/2 inches offset from each other.

- With a ridge board, ceiling joists become rafter ties. These joists work much like the bottom chord of a truss, resisting tension forces that would cause the roof to spread and the ridge to drop. If the ceiling joists do not provide this critical tie or if they do not run parallel, the roof ridge will sag and thrust the exterior walls outward.

Ridge Beam Considerations:

- A structural ridge beam is required when there are no ceiling joists and the ceiling is attached to the rafters. The ridge beam is a structural element that must be capable of resisting the downward force of the rafters. With ridge beam designs, there is no outward force exerted on the exterior walls.

- Where the roof pitch is less than 3:12, structural members that support rafters – such as ridges, hips, and valleys – must be designed as beams and proper bearing provided for rafters.

- Ridge beams generally consist of engineered lumber with supporting columns in the gables. Examples of common engineered lumbers include glue-laminated timber (“glu-lam”) and laminated veneer lumber (“LVL”). Due to span, load, and deflection requirements, ridge beams typically cannot be made from solid-sawn lumber.

Failure to follow these above-mentioned construction requirements will likely cause your roof to sag, which will in turn cause leaning of the corresponding exterior walls. Homeowners should seek guidance on remediation steps from a licensed qualified design professional on remediation steps if their home is presenting roof sag.

Truss Systems

Truss-framed roofs are composed of trusses that are prefabricated in a shop-controlled environment based on specific engineering design criteria. Most truss manufacturers use proprietary methods and specialized software to design trusses in accordance with exact specifications and dimensions of the roof layout.

Trusses are essentially structural frames fabricated from 2-inch-thick dimension lumber (usually 2x4s or 2x6s). Many different truss configurations are possible, including open trusses for attic rooms and cathedral or scissor trusses with sloped top and bottom chords.

There are many advantages to using trusses instead of rafters:

- The first is expense savings – trusses are much cheaper due to their streamlined production and the minimal waste involved in building them.

- Since trusses are delivered directly to the jobsite already assembled, they can be installed much faster. In some cases, crews can install them in a single day.

- Generally, with truss-framed roofs, all loads are bearing on the exterior walls, which allows more open space inside and offers flexibility with respect to the positioning of interior walls.

There are fewer factors that can cause roof issues for those roofs that use a truss system. But these factors are nonetheless important to consider.

First, a truss should never be altered by tradesmen including electricians, HVAC technicians, etc., unless they’re acting under the direction of the licensed engineer. Alterations can considerably weaken the capacity of a truss.

Second, the timely delivery of material, to avoid unnecessary storage or damage to any metal connectors, is critical. Any damage should be repaired as recommended by the manufacturer.

Since most trusses are designed to span the entire width of the structure, the top chord and web members experience a compressive axial force. This axial force can cause distortion and buckling of the truss, potentially knocking it out of plane or alignment, if it is not properly braced during construction. Therefore, it is important that contractors properly brace and hold trusses straight during the installation and erection process, until sheathing is nailed in place.

Finally, home builders must also pay attention to other permanent bracing that’s typically specified by designers, including top chord plane, bottom chord plane, and web member plane bracing, as shown below. Adding a scab brace, for example, can enhance the buckling capacity of a web member.

Concluding Remarks

Hopefully, this article has offered you a clear picture of roof sag and its potential causes. Understanding your own home’s roofing system means you’ll be better able to identify structural issues and their sources.

If you have any questions or concerns regarding your home’s roof system, the team at W.D. Hill Engineering is ready to help. We’ve got the deep experience and expertise to solve a wide array of roof issues. Give us a call today.

Structural Disclaimer:

This article is intended for information purposes only. It is not intended to relieve the user of this article of responsibility for a proper condition assessment and structural evaluation by an experienced licensed qualified design professional.